Flygindustrin utvecklas ständigt, drivet av behovet av mer effektiva, kostnadseffektiva och innovativa lösningar. Traditionella tillverkningsmetoder har ofta svårt att hålla jämna steg med kraven på snabb prototypframställning, lätta komponenter och komplexa geometriska former. 3D-utskrift, eller additiv tillverkning, erbjuder en lovande lösning på dessa utmaningar, och tillhandahåller ett mångsidigt och effektivt sätt att producera flygkomponenter. Denna artikel fördjupar sig i de olika aspekterna av 3D-utskrift inom flygindustrin, och utforskar dess fördelar, tillämpningar och de intrikata detaljerna i dess implementering.

Snabbfix sammanfattningstabell

| Utmaning | Traditionellt tillvägagångssätt | 3D-utskriftslösning | Fördel | Påverkan på flygindustrin |

|---|---|---|---|---|

| Höga produktionskostnader | Dyr verktygstillverkning och arbetskraft | Minskade verktygsbehov | Kostnadsbesparingar | Mer prisvärda komponenter |

| Långa ledtider | Långa inställnings- och produktionscykler | Snabb prototypframställning | Snabbare genomloppstid | Accelererad innovation |

| Komplexa geometrier | Begränsad av bearbetningsmöjligheter | Geometrisk frihet | Designflexibilitet | Förbättrad komponentprestanda |

| Materialavfall | Subtraktiva tillverkningsprocesser | Additiv tillverkning | Minskad avfall | Hållbar produktion |

| Begränsad anpassning | Standardiserade delar | Anpassningsalternativ | Skräddarsydda lösningar | Förbättrad funktionalitet |

Fördelar med 3D-utskrift

3D printing offers numerous advantages over traditional manufacturing techniques, particularly in the aerospace sector. The ability to produce complex geometries without the need for specialized tooling is a game-changer. This geometric freedom allows engineers to design parts that are lighter and stronger, optimizing performance while reducing material usage.

En annan betydande fördel är minskningen av produktionskostnader. Traditionell tillverkning innebär ofta dyra verktyg och arbetsintensiva processer, vilket kan minimeras avsevärt med additiv tillverkning. Genom att bygga komponenter lager för lager minskar 3D-utskrift behovet av överflödigt material, vilket leder till kostnadsbesparingar och en mer hållbar produktionsprocess.

Produktionshastigheten är en annan kritisk fördel. Snabb prototypframställning gör det möjligt för ingenjörer att snabbt iterera design, vilket förkortar utvecklingscykeln och möjliggör snabbare validering och förproduktionstestning. Denna smidighet är avgörande i en bransch där tid till marknad kan vara en betydande konkurrensfördel.

Anpassning är också en stark sida av 3D-utskrift. Förmågan att producera skräddarsydda komponenter anpassade till specifika krav möjliggör förbättrad funktionalitet och prestanda. Detta är särskilt fördelaktigt inom flygindustrin, där varje gram och millimeter räknas.

Tillämpningar inom flygindustrin

Flyg- och rymdindustrin har anammat 3D-utskrift i olika tillämpningar, från prototypframställning till produktion av komponenter för slutanvändning. En av de mest framträdande användningarna är i utvecklingen av lätta strukturer. Genom att använda avancerade material och innovativa designer kan 3D-utskrift producera komponenter som bibehåller styrka samtidigt som vikten minskas avsevärt, en kritisk faktor inom flyg- och rymdutforskning.

3D-utskrift används också i produktionen av komplexa motorkomponenter. Tekniken möjliggör skapandet av intrikata interna geometriska former som skulle vara omöjliga eller oöverkomligt dyra att uppnå med traditionella metoder. Denna kapacitet leder till mer effektiva motorer med förbättrad bränsleförbrukning och minskade utsläpp.

Förutom motorer och strukturella komponenter används 3D-utskrift för att skapa anpassade delar för kabininteriörer. Från sätesbeslag till ventilationssystem, möjligheten att skräddarsy komponenter efter specifika behov förbättrar passagerarkomfort och operativ effektivitet.

Tekniken gör också framsteg inom produktionen av satellitkomponenter. Rymdindustrin drar nytta av den minskade vikten och ökade funktionaliteten hos 3D-utskrivna delar, vilket kan leda till betydande kostnadsbesparingar i uppskjutningsoperationer.

Prototypmetoder

Prototypframställning är en kritisk fas i flyg- och rymddesignprocessen, och 3D-utskrift har revolutionerat detta steg. Möjligheten att snabbt producera prototyper gör att ingenjörer kan testa och förfina designer snabbt, vilket leder till mer effektiva utvecklingscykler.

There are several methods of prototyping using 3D printing, each with its own advantages. Stereolithography (SLA) is known for its high precision and smooth surface finish, making it ideal for detailed models. Selective Laser Sintering (SLS) offers the ability to produce durable and functional prototypes without the need for support structures, allowing for more complex designs. Fused Deposition Modeling (FDM) is often used for creating larger prototypes due to its cost-effectiveness and material versatility.

Dessa metoder gör det möjligt för ingenjörer att validera designer mer effektivt, vilket minskar risken för kostsamma fel i senare produktionsstadier. Möjligheten att snabbt iterera och testa olika konfigurationer är ovärderlig i en industri där innovation är nyckeln.

Materialval

Materialval är en avgörande aspekt av 3D-utskrift inom flyg- och rymdindustrin, eftersom det direkt påverkar prestandan och hållbarheten hos den slutliga produkten. Valet av material beror på flera faktorer, inklusive den avsedda tillämpningen, miljöförhållandena och mekaniska krav.

Metaller som titan, aluminium och nickelbaserade superlegeringar används ofta i flyg- och rymdindustrins 3D-utskrift på grund av deras styrka-till-vikt-förhållanden och motståndskraft mot höga temperaturer. Dessa material är idealiska för att producera motorkomponenter och strukturella delar som måste tåla extrema förhållanden.

Polymerer och kompositer används också i stor utsträckning, särskilt för icke-strukturella komponenter och interiördelar. Avancerade kompositer erbjuder fördelarna av minskad vikt och förbättrade mekaniska egenskaper, vilket gör dem lämpliga för ett brett spektrum av tillämpningar.

Utvecklingen av nya material specifikt utformade för 3D-utskrift är ett pågående forskningsområde, med potential att ytterligare utöka teknikens kapabiliteter och tillämpningar inom flygindustrin.

Designoptimering

Designoptimering är ett kritiskt steg för att utnyttja 3D-utskriftens fulla potential. Tekniken möjliggör skapandet av komplexa geometriska former som tidigare var oåtkomliga, vilket gör det möjligt för ingenjörer att optimera designer för prestanda, vikt och effektivitet.

Topologioptimering är en allmänt använd teknik i detta sammanhang. Genom att använda algoritmer för att simulera och analysera en komponents prestanda under olika förhållanden kan ingenjörer identifiera områden där material kan avlägsnas utan att kompromissa styrkan. Denna process resulterar i lättare, mer effektiva designer som är perfekt lämpade för flygtillämpningar.

Generativ design är en annan metod som utnyttjar 3D-utskriftens kapacitet. Genom att mata in specifika designmål och begränsningar kan ingenjörer använda programvara för att generera flera designiterationer, var och en optimerad för olika kriterier. Denna metod möjliggör utforskning av innovativa lösningar som tänjer på gränserna för traditionell design.

Förmågan att optimera designer på detta sätt förbättrar inte bara prestandan utan bidrar också till materialsparande och kostnadsreduktioner, i linje med industrins mål för effektivitet och hållbarhet.

Produktionsstadier

Produktionsstegen för 3D-utskrift inom flygindustrin involverar flera viktiga steg, var och en kritisk för att säkerställa kvaliteten och prestandan hos den slutliga produkten. Processen börjar med design och modellering, där ingenjörer använder CAD-programvara för att skapa detaljerade digitala representationer av komponenten.

När designen är färdigställd är nästa steg materialförberedelse. Detta innebär att välja lämpligt material och säkerställa att det är i rätt form för den valda 3D-utskriftsmetoden. För metalldelar innebär detta vanligtvis att använda metallpulver, medan polymerer kan vara i filament- eller hartsform.

Den faktiska utskriftsprocessen följer, där komponenten byggs lager för lager enligt den digitala modellen. Detta steg kräver noggrann övervakning för att säkerställa noggrannhet och konsekvens, eftersom eventuella fel kan kompromissa delens integritet.

Efterbearbetning är ett avgörande steg som innebär att ta bort stödstrukturer, ytbehandling och eventuella nödvändiga värmebehandlingar för att förbättra komponentens mekaniska egenskaper. Detta steg är viktigt för att uppfylla de stränga kvalitetsstandarderna inom flygindustrin.

Slutligen genomgår komponenten rigorösa tester och validering för att säkerställa att den uppfyller alla prestanda- och säkerhetskrav. Detta omfattande tillvägagångssätt säkerställer att 3D-utskrivna delar är tillförlitliga och redo för användning i kritiska flygtillämpningar.

Anpassningsalternativ

En av de framstående egenskaperna hos 3D-utskrift är dess förmåga att erbjuda omfattande anpassningsalternativ. Denna kapacitet är särskilt värdefull inom flygindustrin, där komponenter ofta behöver uppfylla specifika krav och begränsningar.

Anpassning kan tillämpas på olika aspekter av en komponent, från dess geometri till dess materialkomposition. Ingenjörer kan skräddarsy designer för att optimera prestanda för specifika tillämpningar, såsom att förbättra aerodynamik eller minska vikt.

Förmågan att producera skräddarsydda komponenter möjliggör också integration av flera funktioner i en enda del. Detta kan leda till mer effektiva designer, minska antalet individuella komponenter som behövs och förenkla monteringsprocesser.

Dessutom sträcker sig anpassning till produktionen av reservdelar. Inom flygindustrin, där stillestånd kan vara kostsamt, säkerställer förmågan att snabbt producera anpassade reservdelar att flygplan kan återgå till tjänst snabbt.

Geometrisk frihet

Geometrisk frihet är en av de mest betydande fördelarna med 3D-utskrift, vilket ger designers möjlighet att skapa komplexa former och strukturer som är svåra eller omöjliga att uppnå med traditionella tillverkningsmetoder.

Denna frihet möjliggör utforskning av innovativa designkoncept, såsom gitterstrukturer och organiska former, som kan förbättra prestanda och effektivitet hos flygkomponenter. Dessa designer resulterar ofta i lättare delar med förbättrade styrka-till-vikt-förhållanden, vilket bidrar till övergripande viktminskning och bränsleeffektivitet.

Förmågan att producera intrikata inre geometrier öppnar också upp nya möjligheter för kylkanaler och vätskedynamik, vilket leder till mer effektiv termisk hantering i motorer och andra kritiska system.

Geometrisk frihet är inte bara fördelaktig för prestanda utan också för estetiska överväganden. Inom flygindustrin, där varumärkesprofilering och passagerarupplevelse är viktiga, kan förmågan att skapa visuellt tilltalande komponenter förbättra den övergripande designen av flygplansinteriörer.

Ytfinish

Ytfinish är en viktig övervägning inom 3D-utskrift, särskilt i flygapplikationer där precision och prestanda är kritiska. Kvaliteten på ytfinishen kan påverka aerodynamisk prestanda, friktion och slitage, vilket gör det till en nyckelfaktor i design och produktion av komponenter.

3D-utskrift erbjuder en rad ytfinishalternativ beroende på vald metod och material. Tekniker som SLA och SLS kan producera delar med släta ytor, lämpliga för applikationer där estetik och precision är viktiga.

Efterbehandlingstekniker, såsom slipning, polering och beläggning, kan ytterligare förbättra ytfinishen, vilket säkerställer att komponenterna uppfyller flygindustrins stränga krav. Dessa processer är avgörande för att uppnå önskad nivå av prestanda och tillförlitlighet.

Förmågan att uppnå högkvalitativa ytor med 3D-utskrift förbättrar inte bara komponenternas funktionalitet utan bidrar också till deras livslängd och hållbarhet, i linje med industrins mål för säkerhet och effektivitet.

Stödstrukturer

Stödstrukturer är en integrerad del av 3D-utskriftsprocessen, särskilt för komplexa geometrier och överhäng. Dessa tillfälliga strukturer ger stabilitet under utskrift, vilket säkerställer att komponenten byggs korrekt och utan deformation.

Design och placering av stödstrukturer kräver noggrann övervägning, eftersom de kan påverka den övergripande effektiviteten och kostnaden för utskriftsprocessen. Ingenjörer måste balansera behovet av stöd med önskan att minimera materialanvändning och efterbehandlingstid.

Framsteg inom mjukvara och utskriftsteknik har lett till utvecklingen av mer effektiva stödstrukturer, vilket minskar mängden material som krävs och förenklar borttagningsprocessen. Detta förbättrar inte bara den övergripande effektiviteten i produktionsprocessen utan bidrar också till materialsparande och kostnadsminskningar.

Inom flygindustrin, där precision och prestanda är avgörande, är förmågan att effektivt hantera stödstrukturer väsentlig för att säkerställa kvaliteten och tillförlitligheten hos 3D-utskrivna komponenter.

3D-utskrift vs traditionell tillverkning

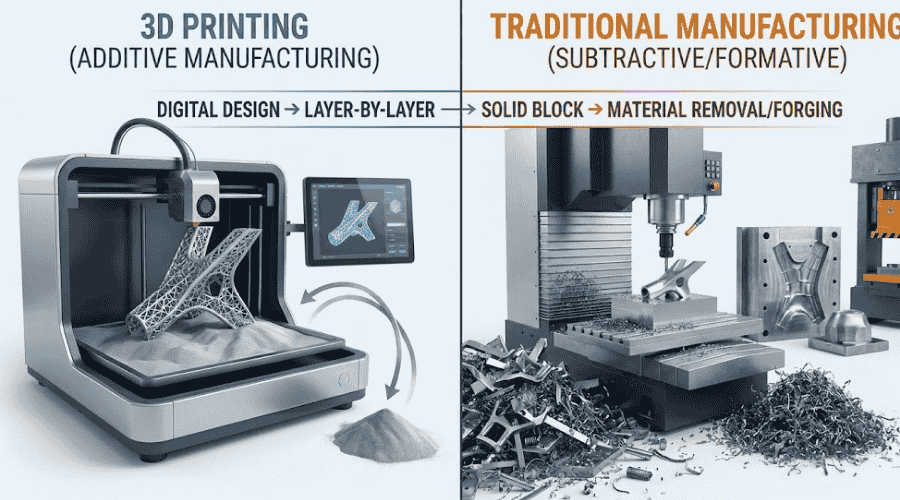

Jämförelsen mellan 3D-utskrift och traditionell tillverkning belyser de unika fördelarna och begränsningarna hos varje metod. Att förstå dessa skillnader är avgörande för att fatta välgrundade beslut inom flygproduktion.

| Aspekt | 3D-utskrift | Traditionell tillverkning |

|---|---|---|

| Produktionshastighet | Snabb prototypframtagning, snabbare iterationer | Längre inställnings- och produktionstider |

| Kostnad | Lägre för små serier, minskad verktygskostnad | Högre för små serier, dyr verktygskostnad |

| Komplexitet | Hög geometrisk frihet, komplexa designer | Begränsad av bearbetningsmöjligheter |

| Materialavfall | Minimal, additiv process | Betydande, subtraktiv process |

| Anpassning | Höga, skräddarsydda lösningar | Begränsade, standardiserade delar |

3D-utskrift utmärker sig inom områden där traditionella metoder brister, särskilt när det gäller hastighet, kostnad och komplexitet. Dess förmåga att producera komplexa geometriska former och anpassade komponenter gör det till ett idealiskt val för flygapplikationer där innovation och effektivitet är nyckeln. Traditionell tillverkning har dock fortfarande fördelar vid storskalig produktion och vissa materialegenskaper, vilket belyser vikten av att välja rätt metod för varje specifik applikation.

Avancerade tillämpningar av 3D-utskrift inom flygindustrin

As the aerospace industry continues to embrace 3D printing, the focus has shifted towards leveraging this technology for more complex and critical applications. One such application is the creation of jigs and fixtures. These tools are essential for the assembly and inspection processes in aerospace manufacturing. By using 3D printing, companies can produce these components with enhanced geometric precision and reduced lead times, allowing for quicker iterations and adjustments.

Another innovative use of 3D printing is in the production of surrogate parts. These are non-functional components used for testing and validation purposes, enabling engineers to assess fit, form, and function without the need for expensive materials or processes. This approach not only saves costs but also accelerates the development cycle.

Delorientering och monteringsfästen

Delorientering är en kritisk faktor inom 3D-utskrift, särskilt i flygapplikationer där precision och prestanda är avgörande. Orienteringen av en del under utskrift kan avsevärt påverka dess ytfinish, styrka och mängden stödmaterial som krävs. Genom att optimera delorienteringen kan tillverkare uppnå bättre ytfinish och strukturell integritet, samtidigt som materialavfallet minimeras.

Monteringsfästen är ett annat område där 3D-utskrift utmärker sig. Dessa komponenter kräver ofta komplexa geometriska former och måste tåla betydande mekaniska belastningar. Genom att använda teknologier som SLA, SLS och DMSL kan tillverkare producera lätta, högstyrkefästen av material som titan. Detta minskar inte bara flygplanets vikt utan förbättrar också dess totala prestanda.

Högdetaljerade prototyper och satellitkomponenter

The ability to produce high-detail prototypes is one of the standout features of 3D printing. In the aerospace sector, this capability is invaluable for visualizing complex designs and conducting thorough evaluations before committing to full-scale production. High-detail prototypes allow engineers to identify potential issues early in the design process, reducing the risk of costly errors.

3D printing also plays a crucial role in the fabrication of satellite components. The geometric freedom offered by additive manufacturing enables the creation of intricate structures that would be impossible with traditional methods. This is particularly beneficial for the production of lightweight, high-strength components that can withstand the harsh conditions of space.

Kostnadsreducering och viktbesparing

En av de främsta fördelarna med 3D-utskrift inom flygindustrin är dess potential för kostnadsreduktion. Genom att konsolidera flera delar till en enda utskriven komponent kan tillverkare minska monteringstiden och arbetskostnaderna. Dessutom eliminerar förmågan att producera delar på begäran behovet av stora lager, vilket ytterligare sänker kostnaderna.

Viktbesparing är en annan betydande fördel med 3D-utskrift. Genom att använda avancerade material och optimera designer för lätta strukturer kan flygbolag minska vikten på sina flygplan och rymdfarkoster. Detta leder till förbättrad bränsleeffektivitet och minskade utsläpp, i linje med industrins mål för hållbarhet.

Prestandaförbättring och minskning av materialavfall

3D printing offers numerous opportunities for performance improvement in aerospace applications. The ability to create complex geometries and integrate multiple functions into a single part enhances the overall performance of aircraft and spacecraft. Moreover, the precision of additive manufacturing ensures that components meet stringent aerospace standards.

Minskning av materialavfall är en annan kritisk fördel med 3D-utskrift. Traditionella tillverkningsmetoder resulterar ofta i betydande materialavfall på grund av processernas subtraktiva natur. I kontrast bygger additiv tillverkning delar lager för lager, och använder endast det material som behövs för slutprodukten. Detta minskar inte bara avfall utan sänker även materialkostnaderna.

Vanliga frågor

F: Vilka material används vanligtvis i 3D-utskrift inom flygindustrin?

S: Vanliga material inkluderar titan, aluminium och högpresterande polymerer. Dessa material erbjuder den nödvändiga styrkan, hållbarheten och lättvikts-egenskaper som krävs för flygapplikationer.

F: Hur bidrar 3D-utskrift till viktbesparingar inom flygindustrin?

S: Genom att möjliggöra komplexa, optimerade konstruktioner och användning av lättviktsmaterial minskar 3D-utskrift avsevärt vikten på komponenter, vilket leder till förbättrad bränsleeffektivitet och prestanda.

F: Vilka är fördelarna med att använda 3D-utskrift för satellitkomponenter?

S: 3D-utskrift möjliggör skapandet av intrikata, lätta strukturer som kan motstå de extrema förhållandena i rymden, vilket förbättrar prestandan och tillförlitligheten hos satellitkomponenter.

Slutsats

3D-utskrift revolutionerar flygindustrin genom att erbjuda oöverträffade möjligheter för innovation och effektivitet. Från att minska kostnader och materialavfall till att förbättra prestanda och möjliggöra komplexa designer, är fördelarna tydliga. För dem som är intresserade av att utforska denna transformativa teknik vidare, erbjuder resurser som “Guide till 3D-utskriftstekniker,” “Introduktion till additiv tillverkning,” och “Design för 3D-utskrift” värdefulla insikter och vägledning. När industrin fortsätter att utvecklas kommer 3D-utskrift utan tvekan att spela en avgörande roll i att forma framtiden för flygtillverkning.