Additive manufacturing, commonly known as 3D printing, is revolutionizing the industrial landscape. As industries strive for efficiency and innovation, the demand for advanced manufacturing techniques is increasing. However, the rapid evolution of this technology presents challenges that must be addressed to fully harness its potential.

クイックフィックス要約表

| 問題 | Quick Fix | 長期的な解決策 | 影響 | 例示産業 |

|---|---|---|---|---|

| High material costs | リサイクル材料を使用する | コスト効率の良い材料を開発する | Reduced production costs | 自動車 |

| 限られたマルチマテリアル能力 | Invest in hybrid printers | 材料の互換性に関する研究 | Enhanced product functionality | 航空宇宙 |

| 生産速度の遅さ | Optimize printing parameters | より速い印刷技術を開発する | スループットの増加 | Consumer Electronics |

| 設計の複雑さの制限 | AI駆動のデザインツールを使用する | Develop advanced CAD software | より大きなデザインの柔軟性 | 医療機器 |

| Lack of skilled workforce | トレーニングプログラムを実施する | 自動化のためにAIを統合する | Increased efficiency and innovation | 一般製造 |

産業用3Dプリンティング

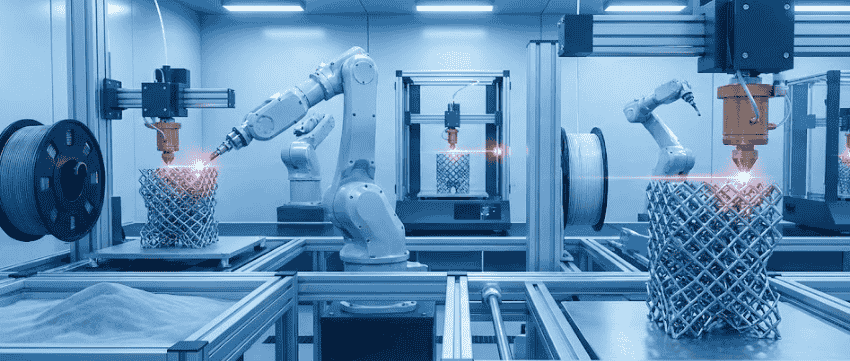

Industrial 3D printing, a subset of additive manufacturing, is transforming production processes across sectors. Unlike traditional manufacturing, which often involves subtractive processes, 3D printing builds objects layer by layer, reducing waste and enabling complex geometries. This technology is particularly beneficial for industries requiring customized solutions, such as aerospace, automotive, and healthcare.

産業用3Dプリンティングの利点:

- Customization and Complexity: Industrial 3D printing allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in industries like aerospace, where intricate designs can lead to improved performance and efficiency.

- Reduced Waste: Traditional manufacturing processes often result in significant material waste. In contrast, additive manufacturing uses only the material necessary to build an object, leading to more sustainable production practices.

- Rapid Prototyping and Production: The ability to quickly produce prototypes accelerates the design and testing phases of product development. This speed also translates to faster production times for end-use parts, reducing time-to-market.

- Cost Efficiency for Low Volume Production: For small batch productions, 3D printing can be more cost-effective than traditional methods, which often require expensive tooling and setup.

- Supply Chain Simplification: By enabling on-demand production, 3D printing can reduce the need for large inventories and complex supply chains, lowering costs and increasing responsiveness to market demands.

産業用3Dプリンティングの課題:

Despite its advantages, industrial 3D printing faces several challenges. High material costs, limited material options, and slower production speeds compared to traditional methods can hinder widespread adoption. Additionally, quality control and standardization remain significant hurdles.

比較表:産業用 vs 試作3Dプリンティング

| 特徴 | Industrial 3D Printing | 試作3Dプリント |

|---|---|---|

| 目的 | End-use part production | 設計とテスト |

| 材料の範囲 | Broad, including metals | 主にプラスチック |

| 生産量 | Medium to high | 低 |

| 速度 | 中から高 | 高い |

| コスト | Higher due to material and setup | 迅速な反復に焦点を当てた低コスト |

| Quality Control | 厳格な | 厳密でない |

マルチマテリアル印刷

Multi-material printing is an emerging trend in additive manufacturing, enabling the creation of objects with varied material properties in a single build process. This capability is crucial for producing parts that require different mechanical, thermal, or aesthetic characteristics.

マルチマテリアルプリンティングの利点:

- Functional Integration: By combining materials with different properties, manufacturers can create parts that perform multiple functions. For example, a single part can have both rigid and flexible sections, reducing the need for assembly and improving product performance.

- Enhanced Product Design: Designers have greater freedom to innovate, as they are no longer constrained by the limitations of single-material manufacturing. This can lead to more ergonomic and efficient designs.

- Cost and Time Efficiency: Multi-material printing can reduce the number of parts needed in an assembly, decreasing production time and costs. It also minimizes the need for post-processing and assembly labor.

マルチマテリアルプリンティングの課題:

The primary challenges include material compatibility and the complexity of managing multiple materials during the printing process. Current technology often requires manual intervention to switch materials, which can slow down production and increase costs. Additionally, developing materials that can seamlessly integrate with each other remains a technical hurdle.

マルチマテリアル vs シングルマテリアルプリンティング

| 特徴 | Multi-Material Printing | シングルマテリアル印刷 |

|---|---|---|

| 複雑さ | High complexity, can integrate multiple properties in one print | Simpler, limited to the properties of one material |

| カスタマイズ | 高いカスタマイズの可能性 | Limited customization options |

| コスト | Generally higher due to material complexity | 簡単さにより低い |

| 応用 | Ideal for products requiring multiple material properties | Suitable for straightforward applications |

| 生産時間 | Longer, due to complexity of processes | 簡単なプロセスにより短い |

| Material Compatibility | 互換性を確保するために慎重な選択が必要 | No compatibility issues |

製造業におけるAI

Artificial Intelligence (AI) is playing a transformative role in the field of additive manufacturing. By enhancing design, optimizing production processes, and improving quality control, AI is helping to overcome some of the limitations of traditional manufacturing methods.

付加製造におけるAIの応用:

- 設計最適化: AI algorithms can analyze vast amounts of data to suggest design improvements that enhance performance and reduce material usage. This capability is particularly useful in industries like aerospace and automotive, where weight reduction is crucial.

- Process Automation: AI can automate various aspects of the 3D printing process, from material selection to machine calibration. This reduces the need for skilled labor and minimizes human error, leading to more consistent production quality.

- Predictive Maintenance: By analyzing machine data, AI can predict when maintenance is required, reducing downtime and extending the lifespan of equipment. This is particularly valuable in industrial settings where machine uptime is critical.

- Quality Assurance: AI can enhance quality control by analyzing real-time data during the printing process to detect defects or deviations from design specifications. This ensures that parts meet the required standards and reduces waste.

AI統合の課題:

Despite its potential, integrating AI into additive manufacturing is not without challenges. High implementation costs, data privacy concerns, and the need for specialized expertise can hinder adoption. Additionally, the reliance on data-driven decision-making requires robust data management systems and infrastructure.

大判プリンティング

Large-format printing represents a significant advancement in additive manufacturing, allowing for the creation of larger components and structures that were previously unfeasible with traditional 3D printing technologies. This capability is transforming industries such as aerospace, construction, and automotive, where the demand for large-scale parts is prevalent.

大判プリンティングの利点

- Cost Efficiency: By producing large parts in a single print, manufacturers can reduce the need for assembly and minimize material wastage.

- Time Savings: The ability to print large objects directly reduces lead times, accelerating the production process.

- Design Flexibility: Large-format printers support complex geometries and can incorporate features that are difficult to achieve with traditional manufacturing methods.

課題と解決策

Despite its advantages, large-format printing faces challenges such as maintaining structural integrity over large spans and ensuring consistent material properties. Machine learning plays a crucial role in addressing these challenges by optimizing print parameters and predicting potential errors.

- Material Consistency: Machine learning algorithms can analyze vast datasets to ensure uniform material distribution and quality.

- Structural Analysis: Predictive models help in assessing the structural integrity of large prints, allowing for adjustments before production begins.

オンデマンドおよび分散型生産

On-demand production, also known as just-in-time manufacturing, leverages additive manufacturing to produce items as needed, rather than maintaining large inventories. Combined with decentralized manufacturing—a shift from traditional centralized production facilities to a network of smaller, distributed manufacturing units—this approach is reshaping how products reach consumers.

利益

- Inventory Reduction: By producing only what is needed, companies can significantly reduce inventory costs.

- カスタマイズ: On-demand production allows for high levels of customization, enabling manufacturers to meet specific customer requirements.

- Sustainability: Reducing overproduction minimizes waste and supports sustainable manufacturing practices.

- Reduced Transportation Costs: By producing goods closer to the point of consumption, transportation costs and associated emissions are minimized.

- Increased Resilience: Decentralized systems are less vulnerable to disruptions, as production can be shifted between locations.

- Local Economic Benefits: Local production supports regional economies and can lead to job creation.

実装の課題

Decentralized manufacturing requires robust logistics and coordination between various production sites. Machine learning can optimize these processes by managing supply chains, predicting potential disruptions, and ensuring seamless communication between units.

材料の制限

Despite its advancements, material limitations remain a significant challenge in additive manufacturing. The range of materials that can be effectively used is narrower compared to traditional manufacturing methods.

材料の多様性と特性

The diversity of materials available for AM is expanding but still limited. Metals, polymers, ceramics, and composites are the primary categories. Each material type has unique properties that influence its suitability for specific applications. Metals like titanium and stainless steel are popular for their strength and durability, making them ideal for aerospace and medical applications. Polymers such as PLA and ABS are favored for prototyping due to their ease of use and cost-effectiveness.

However, the mechanical properties of AM materials often differ from those produced by conventional methods. For instance, AM metals can exhibit anisotropy, where properties vary based on the direction of the print. This can affect the structural integrity and performance of the final product.

材料開発の課題

Developing new materials for AM is a complex process. It requires a deep understanding of material science and the AM process itself. The challenge lies in formulating materials that can withstand the thermal and mechanical stresses during printing while maintaining desired properties. High-temperature polymers and ceramics are still under development for broader use, and these materials are crucial for industries like aerospace and automotive, where parts are exposed to extreme conditions.

品質管理

Ensuring the quality of AM products is critical, particularly in industries where failure can have severe consequences, such as aerospace and healthcare. Quality control in AM involves several aspects, including material quality, dimensional accuracy, and surface finish.

リアルタイムモニタリングとフィードバックシステム

One of the primary challenges in AM quality control is the lack of standardized methods. Traditional quality control techniques are not always applicable due to the unique layer-by-layer construction process. Real-time monitoring systems utilize sensors and cameras to monitor the printing process, ensuring that each layer is correctly deposited. They can detect anomalies such as warping, layer delamination, or incomplete fusion, allowing for corrective actions during the build process.

認証と基準

Organizations like ASTM International and ISO are working towards establishing comprehensive standards for AM processes and materials. These standards aim to ensure that AM products meet specific quality criteria, facilitating their use in critical applications.

後処理の課題

Post-processing is a crucial step in the AM workflow that significantly impacts the final product’s quality and functionality.

表面仕上げと寸法精度

AM parts often have a rough surface due to the layer-by-layer construction process. Several techniques are used to improve surface finish, including sanding, bead blasting, and chemical smoothing. Dimensional accuracy is another critical factor—parts often require machining or grinding to achieve the desired dimensions, adding time and cost to the production process.

機械的特性の向上

Heat treatment processes like annealing and stress relieving improve strength and reduce residual stresses, particularly important for metal parts where internal stresses can lead to cracking or warping.

サポートの除去

Support structures are often necessary in AM to prevent part deformation during printing. However, their removal can be challenging, especially for complex geometries or internal features. Automated support removal systems using advanced algorithms are being developed to address this challenge.

知的財産の課題

The surge in additive manufacturing presents unique challenges in the realm of intellectual property (IP). With the advent of digital design files that can be shared and modified effortlessly, the risk of IP infringement escalates.

知的財産の保護

Unlike traditional manufacturing, where physical molds or dies are necessary, AM relies on digital blueprints that can be disseminated globally with minimal effort. Traditional IP laws are often ill-equipped to address the nuances of digital designs and their subsequent iterations.

知的財産革新の機会

Blockchain technology offers a potential solution by providing a secure, immutable ledger for design files, helping track the provenance of a design. Process patents focusing on unique fabrication methods are becoming increasingly relevant as companies develop proprietary techniques to optimize AM processes.

規制のハードル

As additive manufacturing continues to gain traction, regulatory frameworks struggle to keep pace. The unique aspects of AM, such as its decentralized nature and the ability to produce complex geometries, pose significant challenges to existing regulatory standards.

現在の規制環境

Currently, the regulatory environment for additive manufacturing is fragmented and varies significantly across regions. In the medical field, the U.S. FDA has established guidelines for 3D-printed medical devices. In aerospace, the FAA and EASA are working to develop standards for 3D-printed parts to ensure safety and reliability.

規制調和への道筋

Performance-based standards, which focus on outcomes rather than specific methods, allow for greater flexibility and innovation while ensuring safety. International cooperation is essential for creating harmonized regulatory standards that reduce barriers to entry in the global market.

設計の柔軟性と生成的設計

One of the most significant advantages of additive manufacturing is its unparalleled design flexibility. Unlike traditional manufacturing methods, which often impose constraints due to tooling and material limitations, AM allows for the creation of complex geometries and customized products with ease.

The design flexibility offered by AM enables the production of intricate structures that would be impossible or prohibitively expensive to achieve with conventional methods. This capability is particularly valuable in aerospace for lightweight, optimized structures and in medicine for personalized implants and prosthetics.

Generative design leverages artificial intelligence and machine learning to explore a vast array of design possibilities. By inputting specific parameters and constraints, designers can generate optimized solutions that take full advantage of AM’s capabilities, leading to more innovative and efficient products.

サプライチェーンの革新

Additive manufacturing is revolutionizing supply chain dynamics by enabling on-demand manufacturing closer to the point of consumption. Companies can reduce transportation costs, decrease lead times, and minimize inventory levels. The ability to produce parts on-demand also mitigates risks associated with supply chain disruptions from geopolitical tensions, natural disasters, or pandemics.

ISO認証

ISO certification in additive manufacturing ensures consistent quality and safety standards across the industry. It provides a framework for best practices, helping manufacturers achieve optimal performance and reliability.

主要なISO基準

- ISO/ASTM 52900: Provides a comprehensive overview of terminology used in additive manufacturing.

- ISO/ASTM 52901: Outlines requirements for the qualification of processes and equipment.

- ISO/ASTM 52915: Specifies requirements for digital data used in additive manufacturing.

Achieving ISO certification involves rigorous assessment and compliance with relevant standards. The benefits include enhanced credibility, improved customer confidence, and access to new markets.

よくある質問

付加製造はどのように効率を向上させていますか?

Additive manufacturing improves efficiency through faster printing technologies, new high-performance materials, and advanced design software. These innovations contribute to reduced production times and waste, enabling manufacturers to produce high-quality parts more quickly and cost-effectively.

付加製造はサプライチェーンの革新にどのような役割を果たしていますか?

AM enables decentralized production, enhances customization and flexibility, and mitigates risks associated with disruptions. By allowing on-demand manufacturing closer to the point of consumption, companies can reduce transportation costs, decrease lead times, and maintain continuity of supply.

付加製造においてISO認証が重要な理由は何ですか?

ISO certification ensures consistent quality and safety standards, facilitates international trade, and

enhances credibility. By adhering to globally recognized standards, manufacturers can assure clients of theircommitment to quality and gain a competitive edge in the global market.

The future of additive manufacturing is promising, with significant potential to transform industries and redefine the boundaries of what is possible. Key challenges remain in intellectual property protection, regulatory frameworks, material development, quality control, and post-processing. However, ongoing research and technological advancements are addressing these issues.

By developing innovative IP protection strategies, fostering regulatory harmonization, embracing design flexibility, and ensuring quality through ISO certification, companies can unlock new opportunities for growth and innovation. As the technology continues to evolve, collaboration between industry stakeholders, regulatory bodies, and academia will be essential in shaping a future where additive manufacturing plays a central role in the global economy.

For those interested in exploring related topics, consider reading our guides on “How AI is Transforming Manufacturing,” “The Benefits of Multi-Material 3D Printing,” and “Understanding Large-Format 3D Printing.”