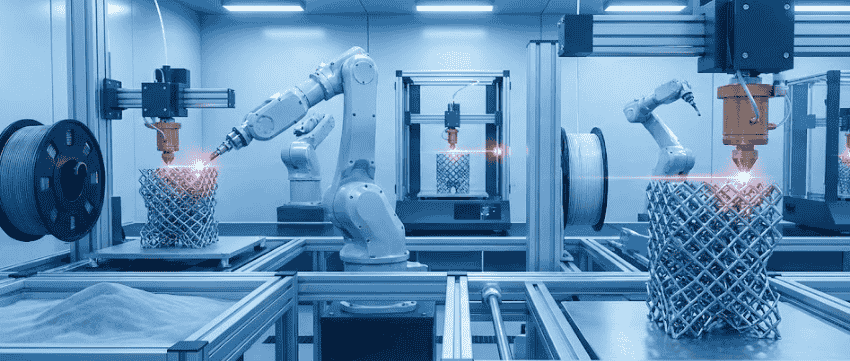

Additive manufacturing, commonly known as 3D printing, is revolutionizing the industrial landscape. As industries strive for efficiency and innovation, the demand for advanced manufacturing techniques is increasing. However, the rapid evolution of this technology presents challenges that must be addressed to fully harness its potential.

ตารางสรุปการแก้ไขด่วน

| ปัญหา | Quick Fix | การแก้ปัญหาระยะยาว | ผลกระทบ | ตัวอย่างอุตสาหกรรม |

|---|---|---|---|---|

| High material costs | ใช้วัสดุรีไซเคิล | พัฒนาวัสดุที่มีต้นทุนประหยัด | Reduced production costs | ยานยนต์ |

| ความสามารถในการใช้วัสดุหลายชนิดที่จำกัด | Invest in hybrid printers | วิจัยเกี่ยวกับความเข้ากันได้ของวัสดุ | Enhanced product functionality | อวกาศ |

| ความเร็วในการผลิตช้า | Optimize printing parameters | พัฒนาเทคโนโลยีการพิมพ์ที่เร็วขึ้น | เพิ่มปริมาณการผลิต | Consumer Electronics |

| ข้อจำกัดด้านความซับซ้อนในการออกแบบ | ใช้เครื่องมือออกแบบที่ขับเคลื่อนด้วย AI | Develop advanced CAD software | ความยืดหยุ่นในการออกแบบที่มากขึ้น | อุปกรณ์ทางการแพทย์ |

| Lack of skilled workforce | ดำเนินการโปรแกรมฝึกอบรม | ผสาน AI สำหรับการทำงานอัตโนมัติ | Increased efficiency and innovation | การผลิตทั่วไป |

การพิมพ์ 3 มิติในอุตสาหกรรม

Industrial 3D printing, a subset of additive manufacturing, is transforming production processes across sectors. Unlike traditional manufacturing, which often involves subtractive processes, 3D printing builds objects layer by layer, reducing waste and enabling complex geometries. This technology is particularly beneficial for industries requiring customized solutions, such as aerospace, automotive, and healthcare.

ข้อดีของการพิมพ์ 3 มิติในอุตสาหกรรม:

- Customization and Complexity: Industrial 3D printing allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This capability is particularly valuable in industries like aerospace, where intricate designs can lead to improved performance and efficiency.

- Reduced Waste: Traditional manufacturing processes often result in significant material waste. In contrast, additive manufacturing uses only the material necessary to build an object, leading to more sustainable production practices.

- Rapid Prototyping and Production: The ability to quickly produce prototypes accelerates the design and testing phases of product development. This speed also translates to faster production times for end-use parts, reducing time-to-market.

- Cost Efficiency for Low Volume Production: For small batch productions, 3D printing can be more cost-effective than traditional methods, which often require expensive tooling and setup.

- Supply Chain Simplification: By enabling on-demand production, 3D printing can reduce the need for large inventories and complex supply chains, lowering costs and increasing responsiveness to market demands.

ความท้าทายในการพิมพ์ 3 มิติในอุตสาหกรรม:

Despite its advantages, industrial 3D printing faces several challenges. High material costs, limited material options, and slower production speeds compared to traditional methods can hinder widespread adoption. Additionally, quality control and standardization remain significant hurdles.

ตารางเปรียบเทียบ: การพิมพ์ 3 มิติในอุตสาหกรรม vs การพิมพ์ต้นแบบ

| คุณสมบัติ | Industrial 3D Printing | การพิมพ์ 3 มิติแบบต้นแบบ |

|---|---|---|

| วัตถุประสงค์ | End-use part production | การออกแบบและการทดสอบ |

| ช่วงของวัสดุ | Broad, including metals | ส่วนใหญ่เป็นพลาสติก |

| ปริมาณการผลิต | Medium to high | ต่ำ |

| ความเร็ว | ปานกลางถึงสูง | สูง |

| ต้นทุน | Higher due to material and setup | ต่ำกว่า มุ่งเน้นที่การทำซ้ำอย่างรวดเร็ว |

| Quality Control | เข้มงวด | เข้มงวดน้อยลง |

การพิมพ์หลายวัสดุ

Multi-material printing is an emerging trend in additive manufacturing, enabling the creation of objects with varied material properties in a single build process. This capability is crucial for producing parts that require different mechanical, thermal, or aesthetic characteristics.

ประโยชน์ของการพิมพ์หลายวัสดุ:

- Functional Integration: By combining materials with different properties, manufacturers can create parts that perform multiple functions. For example, a single part can have both rigid and flexible sections, reducing the need for assembly and improving product performance.

- Enhanced Product Design: Designers have greater freedom to innovate, as they are no longer constrained by the limitations of single-material manufacturing. This can lead to more ergonomic and efficient designs.

- Cost and Time Efficiency: Multi-material printing can reduce the number of parts needed in an assembly, decreasing production time and costs. It also minimizes the need for post-processing and assembly labor.

ความท้าทายของการพิมพ์หลายวัสดุ:

The primary challenges include material compatibility and the complexity of managing multiple materials during the printing process. Current technology often requires manual intervention to switch materials, which can slow down production and increase costs. Additionally, developing materials that can seamlessly integrate with each other remains a technical hurdle.

การพิมพ์หลายวัสดุ vs การพิมพ์วัสดุเดียว

| คุณสมบัติ | Multi-Material Printing | การพิมพ์วัสดุเดียว |

|---|---|---|

| ความซับซ้อน | High complexity, can integrate multiple properties in one print | Simpler, limited to the properties of one material |

| การปรับแต่ง | ศักยภาพในการปรับแต่งสูง | Limited customization options |

| ต้นทุน | Generally higher due to material complexity | ต่ำกว่าเนื่องจากความเรียบง่าย |

| การใช้งาน | Ideal for products requiring multiple material properties | Suitable for straightforward applications |

| เวลาการผลิต | Longer, due to complexity of processes | สั้นกว่าเนื่องจากกระบวนการที่ง่ายกว่า |

| Material Compatibility | ต้องเลือกอย่างระมัดระวังเพื่อให้แน่ใจว่ามีความเข้ากันได้ | No compatibility issues |

ปัญญาประดิษฐ์ในอุตสาหกรรมการผลิต

Artificial Intelligence (AI) is playing a transformative role in the field of additive manufacturing. By enhancing design, optimizing production processes, and improving quality control, AI is helping to overcome some of the limitations of traditional manufacturing methods.

การประยุกต์ใช้ AI ในการผลิตแบบเติมเนื้อวัสดุ:

- การเพิ่มประสิทธิภาพการออกแบบ: AI algorithms can analyze vast amounts of data to suggest design improvements that enhance performance and reduce material usage. This capability is particularly useful in industries like aerospace and automotive, where weight reduction is crucial.

- Process Automation: AI can automate various aspects of the 3D printing process, from material selection to machine calibration. This reduces the need for skilled labor and minimizes human error, leading to more consistent production quality.

- Predictive Maintenance: By analyzing machine data, AI can predict when maintenance is required, reducing downtime and extending the lifespan of equipment. This is particularly valuable in industrial settings where machine uptime is critical.

- Quality Assurance: AI can enhance quality control by analyzing real-time data during the printing process to detect defects or deviations from design specifications. This ensures that parts meet the required standards and reduces waste.

ความท้าทายของการบูรณาการ AI:

Despite its potential, integrating AI into additive manufacturing is not without challenges. High implementation costs, data privacy concerns, and the need for specialized expertise can hinder adoption. Additionally, the reliance on data-driven decision-making requires robust data management systems and infrastructure.

การพิมพ์ขนาดใหญ่

Large-format printing represents a significant advancement in additive manufacturing, allowing for the creation of larger components and structures that were previously unfeasible with traditional 3D printing technologies. This capability is transforming industries such as aerospace, construction, and automotive, where the demand for large-scale parts is prevalent.

ข้อดีของการพิมพ์ขนาดใหญ่

- Cost Efficiency: By producing large parts in a single print, manufacturers can reduce the need for assembly and minimize material wastage.

- Time Savings: The ability to print large objects directly reduces lead times, accelerating the production process.

- Design Flexibility: Large-format printers support complex geometries and can incorporate features that are difficult to achieve with traditional manufacturing methods.

ความท้าทายและวิธีแก้ไข

Despite its advantages, large-format printing faces challenges such as maintaining structural integrity over large spans and ensuring consistent material properties. Machine learning plays a crucial role in addressing these challenges by optimizing print parameters and predicting potential errors.

- Material Consistency: Machine learning algorithms can analyze vast datasets to ensure uniform material distribution and quality.

- Structural Analysis: Predictive models help in assessing the structural integrity of large prints, allowing for adjustments before production begins.

การผลิตตามความต้องการและการกระจายการผลิต

On-demand production, also known as just-in-time manufacturing, leverages additive manufacturing to produce items as needed, rather than maintaining large inventories. Combined with decentralized manufacturing—a shift from traditional centralized production facilities to a network of smaller, distributed manufacturing units—this approach is reshaping how products reach consumers.

ประโยชน์

- Inventory Reduction: By producing only what is needed, companies can significantly reduce inventory costs.

- การปรับแต่ง: On-demand production allows for high levels of customization, enabling manufacturers to meet specific customer requirements.

- Sustainability: Reducing overproduction minimizes waste and supports sustainable manufacturing practices.

- Reduced Transportation Costs: By producing goods closer to the point of consumption, transportation costs and associated emissions are minimized.

- Increased Resilience: Decentralized systems are less vulnerable to disruptions, as production can be shifted between locations.

- Local Economic Benefits: Local production supports regional economies and can lead to job creation.

ความท้าทายในการดำเนินการ

Decentralized manufacturing requires robust logistics and coordination between various production sites. Machine learning can optimize these processes by managing supply chains, predicting potential disruptions, and ensuring seamless communication between units.

ข้อจำกัดของวัสดุ

Despite its advancements, material limitations remain a significant challenge in additive manufacturing. The range of materials that can be effectively used is narrower compared to traditional manufacturing methods.

ความหลากหลายและคุณสมบัติของวัสดุ

The diversity of materials available for AM is expanding but still limited. Metals, polymers, ceramics, and composites are the primary categories. Each material type has unique properties that influence its suitability for specific applications. Metals like titanium and stainless steel are popular for their strength and durability, making them ideal for aerospace and medical applications. Polymers such as PLA and ABS are favored for prototyping due to their ease of use and cost-effectiveness.

However, the mechanical properties of AM materials often differ from those produced by conventional methods. For instance, AM metals can exhibit anisotropy, where properties vary based on the direction of the print. This can affect the structural integrity and performance of the final product.

ความท้าทายในการพัฒนาวัสดุ

Developing new materials for AM is a complex process. It requires a deep understanding of material science and the AM process itself. The challenge lies in formulating materials that can withstand the thermal and mechanical stresses during printing while maintaining desired properties. High-temperature polymers and ceramics are still under development for broader use, and these materials are crucial for industries like aerospace and automotive, where parts are exposed to extreme conditions.

การควบคุมคุณภาพ

Ensuring the quality of AM products is critical, particularly in industries where failure can have severe consequences, such as aerospace and healthcare. Quality control in AM involves several aspects, including material quality, dimensional accuracy, and surface finish.

ระบบการตรวจสอบและป้อนกลับแบบเรียลไทม์

One of the primary challenges in AM quality control is the lack of standardized methods. Traditional quality control techniques are not always applicable due to the unique layer-by-layer construction process. Real-time monitoring systems utilize sensors and cameras to monitor the printing process, ensuring that each layer is correctly deposited. They can detect anomalies such as warping, layer delamination, or incomplete fusion, allowing for corrective actions during the build process.

การรับรองและมาตรฐาน

Organizations like ASTM International and ISO are working towards establishing comprehensive standards for AM processes and materials. These standards aim to ensure that AM products meet specific quality criteria, facilitating their use in critical applications.

ความท้าทายหลังการประมวลผล

Post-processing is a crucial step in the AM workflow that significantly impacts the final product’s quality and functionality.

การตกแต่งพื้นผิวและความแม่นยำของมิติ

AM parts often have a rough surface due to the layer-by-layer construction process. Several techniques are used to improve surface finish, including sanding, bead blasting, and chemical smoothing. Dimensional accuracy is another critical factor—parts often require machining or grinding to achieve the desired dimensions, adding time and cost to the production process.

การเพิ่มคุณสมบัติทางกล

Heat treatment processes like annealing and stress relieving improve strength and reduce residual stresses, particularly important for metal parts where internal stresses can lead to cracking or warping.

การถอดการสนับสนุน

Support structures are often necessary in AM to prevent part deformation during printing. However, their removal can be challenging, especially for complex geometries or internal features. Automated support removal systems using advanced algorithms are being developed to address this challenge.

ความท้าทายด้านทรัพย์สินทางปัญญา

The surge in additive manufacturing presents unique challenges in the realm of intellectual property (IP). With the advent of digital design files that can be shared and modified effortlessly, the risk of IP infringement escalates.

การปกป้องทรัพย์สินทางปัญญา

Unlike traditional manufacturing, where physical molds or dies are necessary, AM relies on digital blueprints that can be disseminated globally with minimal effort. Traditional IP laws are often ill-equipped to address the nuances of digital designs and their subsequent iterations.

โอกาสในการสร้างสรรค์นวัตกรรมด้านทรัพย์สินทางปัญญา

Blockchain technology offers a potential solution by providing a secure, immutable ledger for design files, helping track the provenance of a design. Process patents focusing on unique fabrication methods are becoming increasingly relevant as companies develop proprietary techniques to optimize AM processes.

อุปสรรคด้านกฎระเบียบ

As additive manufacturing continues to gain traction, regulatory frameworks struggle to keep pace. The unique aspects of AM, such as its decentralized nature and the ability to produce complex geometries, pose significant challenges to existing regulatory standards.

ภูมิทัศน์ด้านกฎระเบียบในปัจจุบัน

Currently, the regulatory environment for additive manufacturing is fragmented and varies significantly across regions. In the medical field, the U.S. FDA has established guidelines for 3D-printed medical devices. In aerospace, the FAA and EASA are working to develop standards for 3D-printed parts to ensure safety and reliability.

เส้นทางสู่การประสานงานด้านกฎระเบียบ

Performance-based standards, which focus on outcomes rather than specific methods, allow for greater flexibility and innovation while ensuring safety. International cooperation is essential for creating harmonized regulatory standards that reduce barriers to entry in the global market.

ความยืดหยุ่นในการออกแบบและการออกแบบเชิงสร้างสรรค์

One of the most significant advantages of additive manufacturing is its unparalleled design flexibility. Unlike traditional manufacturing methods, which often impose constraints due to tooling and material limitations, AM allows for the creation of complex geometries and customized products with ease.

The design flexibility offered by AM enables the production of intricate structures that would be impossible or prohibitively expensive to achieve with conventional methods. This capability is particularly valuable in aerospace for lightweight, optimized structures and in medicine for personalized implants and prosthetics.

Generative design leverages artificial intelligence and machine learning to explore a vast array of design possibilities. By inputting specific parameters and constraints, designers can generate optimized solutions that take full advantage of AM’s capabilities, leading to more innovative and efficient products.

นวัตกรรมในห่วงโซ่อุปทาน

Additive manufacturing is revolutionizing supply chain dynamics by enabling on-demand manufacturing closer to the point of consumption. Companies can reduce transportation costs, decrease lead times, and minimize inventory levels. The ability to produce parts on-demand also mitigates risks associated with supply chain disruptions from geopolitical tensions, natural disasters, or pandemics.

การรับรองมาตรฐาน ISO

ISO certification in additive manufacturing ensures consistent quality and safety standards across the industry. It provides a framework for best practices, helping manufacturers achieve optimal performance and reliability.

มาตรฐาน ISO ที่สำคัญ

- ISO/ASTM 52900: Provides a comprehensive overview of terminology used in additive manufacturing.

- ISO/ASTM 52901: Outlines requirements for the qualification of processes and equipment.

- ISO/ASTM 52915: Specifies requirements for digital data used in additive manufacturing.

Achieving ISO certification involves rigorous assessment and compliance with relevant standards. The benefits include enhanced credibility, improved customer confidence, and access to new markets.

คำถามที่พบบ่อย

การผลิตแบบเติมเนื้อวัสดุช่วยเพิ่มประสิทธิภาพได้อย่างไร?

Additive manufacturing improves efficiency through faster printing technologies, new high-performance materials, and advanced design software. These innovations contribute to reduced production times and waste, enabling manufacturers to produce high-quality parts more quickly and cost-effectively.

การผลิตแบบเติมเนื้อวัสดุมีบทบาทอย่างไรในการสร้างสรรค์นวัตกรรมในห่วงโซ่อุปทาน?

AM enables decentralized production, enhances customization and flexibility, and mitigates risks associated with disruptions. By allowing on-demand manufacturing closer to the point of consumption, companies can reduce transportation costs, decrease lead times, and maintain continuity of supply.

ทำไมการรับรอง ISO จึงสำคัญในการผลิตแบบเติมเนื้อวัสดุ?

ISO certification ensures consistent quality and safety standards, facilitates international trade, and

enhances credibility. By adhering to globally recognized standards, manufacturers can assure clients of theircommitment to quality and gain a competitive edge in the global market.

The future of additive manufacturing is promising, with significant potential to transform industries and redefine the boundaries of what is possible. Key challenges remain in intellectual property protection, regulatory frameworks, material development, quality control, and post-processing. However, ongoing research and technological advancements are addressing these issues.

By developing innovative IP protection strategies, fostering regulatory harmonization, embracing design flexibility, and ensuring quality through ISO certification, companies can unlock new opportunities for growth and innovation. As the technology continues to evolve, collaboration between industry stakeholders, regulatory bodies, and academia will be essential in shaping a future where additive manufacturing plays a central role in the global economy.

For those interested in exploring related topics, consider reading our guides on “How AI is Transforming Manufacturing,” “The Benefits of Multi-Material 3D Printing,” and “Understanding Large-Format 3D Printing.”